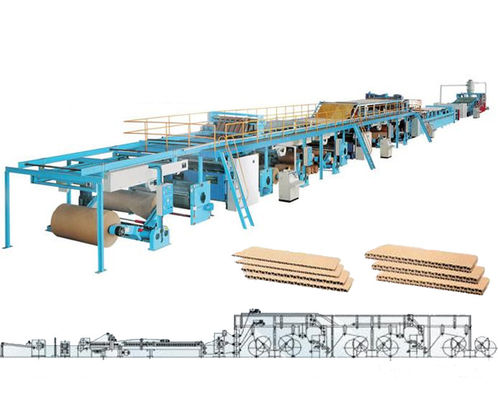

Automatic Electric E Flute Cardboard 5 Ply Corrugated Board Production Line

Basic structure:

1. mill roll stand , 2. single facer 3. preheater 4. bridge 5.double preheater 6. glue machine 7. double facer

8, dryer: 1 set

The dryer is provided with 5 meters and 5 sets of electric heating and drying devices. The drying roller has a diameter of 240 mm, and the surface is plated with hard chrome and pneumatically pressurized.

10, cooling device: 1 set

The cooling device is set to 7m8 group, including upper and lower fan cooling and setting device, frame, guide roller device and pressure roller device.

11, conveying slitting machine: 1 set

The machine is composed of a conveying unit, a paper separating unit, a pressing device, a frame portion and a transmission unit.

The conveying is to send the bonded paper to the cutting machine at a uniform speed and then send it to the cross-cutting machine to make the cross-cut even and accurate.

There are three slitting knives in the separation section, which can be cut and cut.

12, computer spiral knife cross cutting machine: 1 set

The machine is composed of a paper cutting part, a conveying part, an output part, an electric control part, a lubrication part, a frame part and the like.

The cutter shaft diameter of the paper cutting part is 240mm

The conveying output part is controlled by a separate 2.2KW speed regulating motor, which is adjusted with the conveying slitting machine, bonding machine and coating machine.

The electronic control part is composed of 11KW servo motor and corresponding control.

All the gears of the cross-cut paper are ground to ensure the transmission precision and various fatigue resistance of each transmission part.

13, semi-automatic delivery:

The delivery machine conveys the cut cardboard through the plate conveying device, thereby improving work efficiency and being easy to stack. (suitable for uniform production and avoid errors.

Parameter

| Design speed:100m/min | Normal work speed:60-80m/min | ||||

| No. | Machine name | Qty | Remarks | ||

| 1 | Mill roll stand | 5 | Electric swing | ||

| 2 | Railing and tracks | 10 | |||

| 3 | Single facer | 2 | Corrugating roller ¢280mm, electric adjust gluing width, pneumatic control | ||

| 4 | Pre-heater | 2 | ¢600mm, electric adjust wrapping angle | ||

| 5 | Pre-conditioner | 2 | ¢600mm electric adjust wrapping angle | ||

| 6 | Bridge conveyer | 1 | Adsorption type, electric deviation-correcting | ||

| 7 | Triplex pre-heater | 1 | ¢600mm electric adjust wrapping angle | ||

| 8 | Gluing machine | 1 | Pneumatic adjust pressing roller | ||

| 9 | Double facer | 1 | Heating plants: 520mm×16, with cooling section | ||

| 10 | Slitter scorer | 1 | 5 blades with 8 scorers | ||

| 11 | NC cutoff | 1 | Helical knives Blade made in Taiwan | ||

| 12 | Cardboard feeing machine | 1 | |||

| 13 | Main drive | 1 | |||

| 14 | Glue making system | 1 | Automatic circle glue, pipeline provided by buyer | ||

| 15 | Electric system | 1 | |||

| 16 | Steam system | 1 | Pipeline on valves provided by buyer | ||

| 17 | Pneumatic system | 1 | |||

![]()

![]()